PT61 float and thermostatic (internal air vent) steam traps are designed for draining condensate from all types of low and medium pressure steam heating and process equipment.

Modulating discharge. Discharges condensate at steam temperature. Excellent air venting (by thermostatic air vent).

220 oC

16 bar(g)

CAST IRON

End connection: Screwed NPT / BSPT /BSP

| NO. | PART | MATERIAL | QTY. (Nos.) |

|---|---|---|---|

| 1. | BODY | CAST IRON | 1 |

| 2. | COVER | IS: 200 FG200 | 1 |

| 3. | GASKET (COVER) | GRAPHITE WITH SS REINFORCEMENT | 1 |

| 4. | VALVE SEAT | AISI 410/ AISI 420 | 1 |

| 5. | VALVE | AISI 410/ AISI 420 | 1 |

| 6. | LEVER | AISI 304 | 1 |

| 7. | FLOAT | AISI 304 | 1 |

| 8. | AIR VENT ASSLY. | AISI 304 | 1 |

| 9. | BOLT | HIGH TENSILE | 4 |

| 10. | DRAIN PLUG | C.S | 1 |

| 11. | GASKET DRAIN PLUG | COPPER | 1 |

| 12. | GASKET AIR VENT | COPPER | 1 |

| 13. | GASKET VALVE SEAT | COPPER | 1 |

| 14. | BRACKET ASSLY. | AISI 304 | 1 |

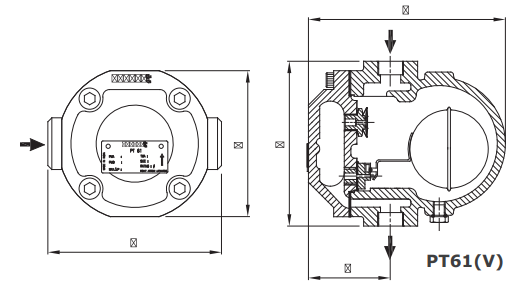

| SIZE | A | B | C | D | Wt. |

|---|---|---|---|---|---|

| DN15, 20 | 130 | 146 | 59 | 110 | 3.3 kg |

| DN25 | 145 | 162 | 66 | 110 | 4.3 kg |

1) Inlet Pressure in bar(g)

2) Back Pressure in bar(g)

3) Operating Temperature in oC

4) Condensate Load in kg/hr

5) Size & Model

6) Horizontal/Vertical

7) End Connections

8) Flow Direction

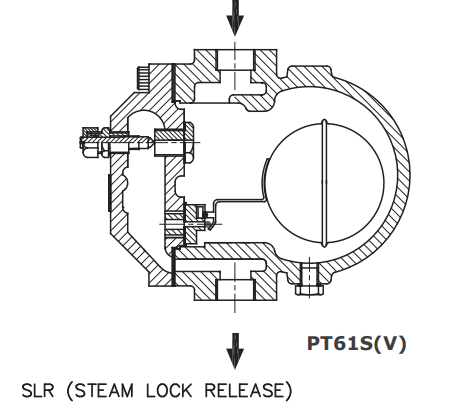

9) Type required with SLR with thermostatic Air Vent and SLR