Thermodynamic steam trap in alloy steel construction with full stainless steel internals. Best suited for medium/high pressure line drains, with low to medium condensate load.

Complete stainless steel internals ensure better mechanical & corrosion resistance properties. Condensate entry below the disc, concentric to the disc/seat ensures a clean & parallel lift of the disc with reference to the seat, eliminating localised wear & tear.

510 oC

65 bar(g)

A217 Gr. WC6

End connection: Socket Weld / Flanged

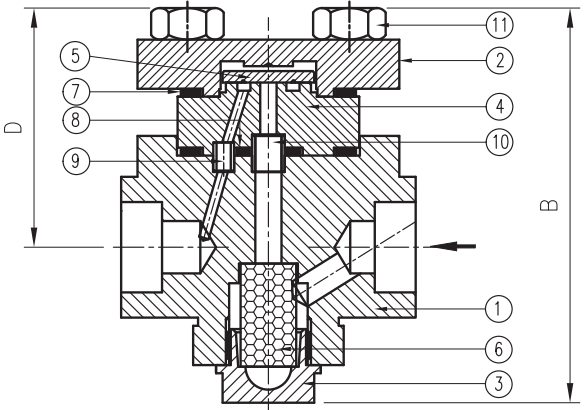

| NO. | PART | MATERIAL | QTY. (Nos.) |

|---|---|---|---|

| 1 | BODY | ASTM A217 Gr. WC6 | 01 |

| 2 | COVER | ASTM A217 Gr. WC6 | 01 |

| 3 | STRAINER CAP | ASTM A217 Gr. WC6 | 01 |

| 4 | DISC SEAT | ASTM A681 Gr. D2 | 01 |

| 5 | DISC | ASTM A681 Gr. D2 | 01 |

| 6 | STRAINER SCREEN | AISI 304 (Ø0.8 PERF) | 02 |

| 7 | GASKET | SPIRAL WOUND SS 304 WITH GRAFOIL FILLER | 01 |

| 8 | GASKET | SPIRAL WOUND SS 304 | 01 |

| 9 | TUBE | AISI 304 | 01 |

| 10 | LOCATOR | AISI 304 | 01 |

| 11 | BOLT | ASTM A193 Gr. B16 | 04 |

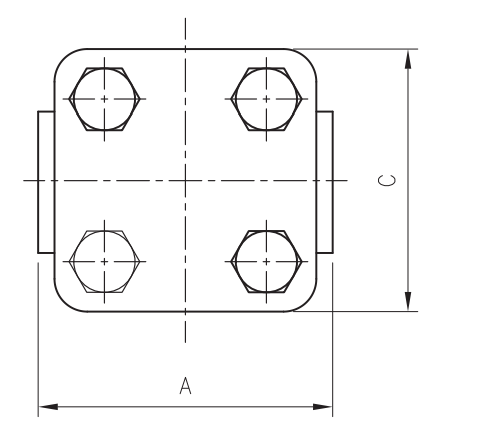

| END CONNS. | SIZE | A | B | C | D | Wt. |

|---|---|---|---|---|---|---|

| SOCKET WELD | DN15, 20 | 90 | 120 | 80 | 73 | 2.5 kg |

1) Inlet Pressure in bar(g)

2) Back Pressure in bar(g)

3) Operating Temperature in oC

4) Condensate Load in kg/hr

5) Size & Model

6) End Connections

7) IBR/Non-lBR