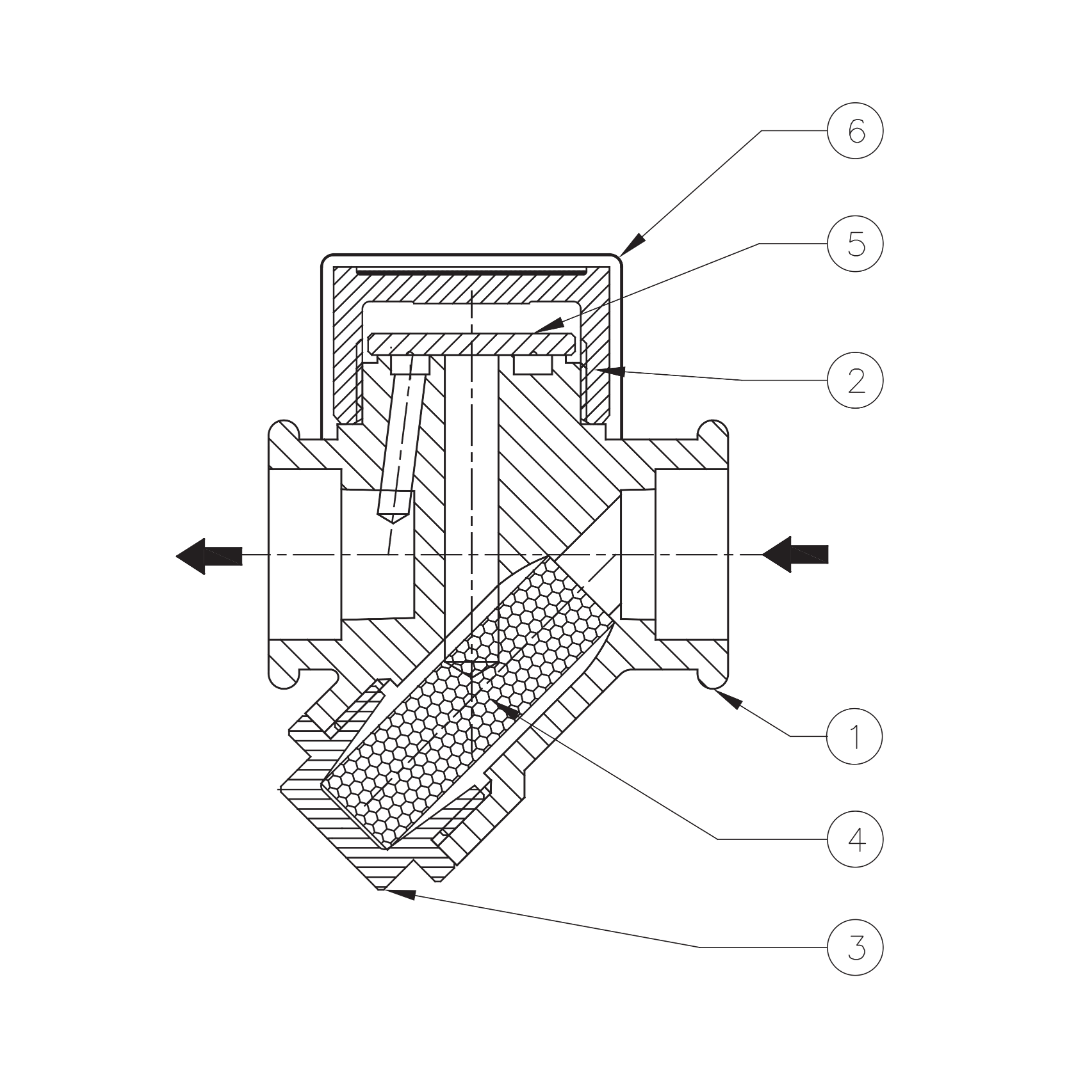

Thermodynamic steam trap with inbuilt strainer in full stainless steel construction, best suited for header and main line drains and drip legs.

Complete stainless steel construction ensures better mechanical and corrosion resistance properties. The disc and seat are hardened by a special induction hardening process with seat harder than disc, to withstand continuous, prolonged operation.

426 oC

21 bar(g)

A743 Gr. CA40

End connection: Screwed NPT / BSPT /BSP / Socket weld/ Flanged

| NO. | PART | MATERIAL | QTY. (Nos.) |

|---|---|---|---|

| 1 | BODY (Seat Hardened) | ASTM A743 Gr CA 40 (Cast Equiv. AISI 420) | 01 |

| 2 | DISC CAP | ASTM A743 Gr CA 40 (Cast Equiv. AISI 420) | 01 |

| 3 | STRAINER CAP | ASTM A743 Gr CA 40 (Cast Equiv. AISI 420) | 01 |

| 4 | STRAINER SCREEN | AISI 304 (Perforated Sheet 0.8) | 01 |

| 5 | DISC (Hardened) | AISI 410 | 01 |

| 6 | ISOTUB | AISI 304 | 01 |

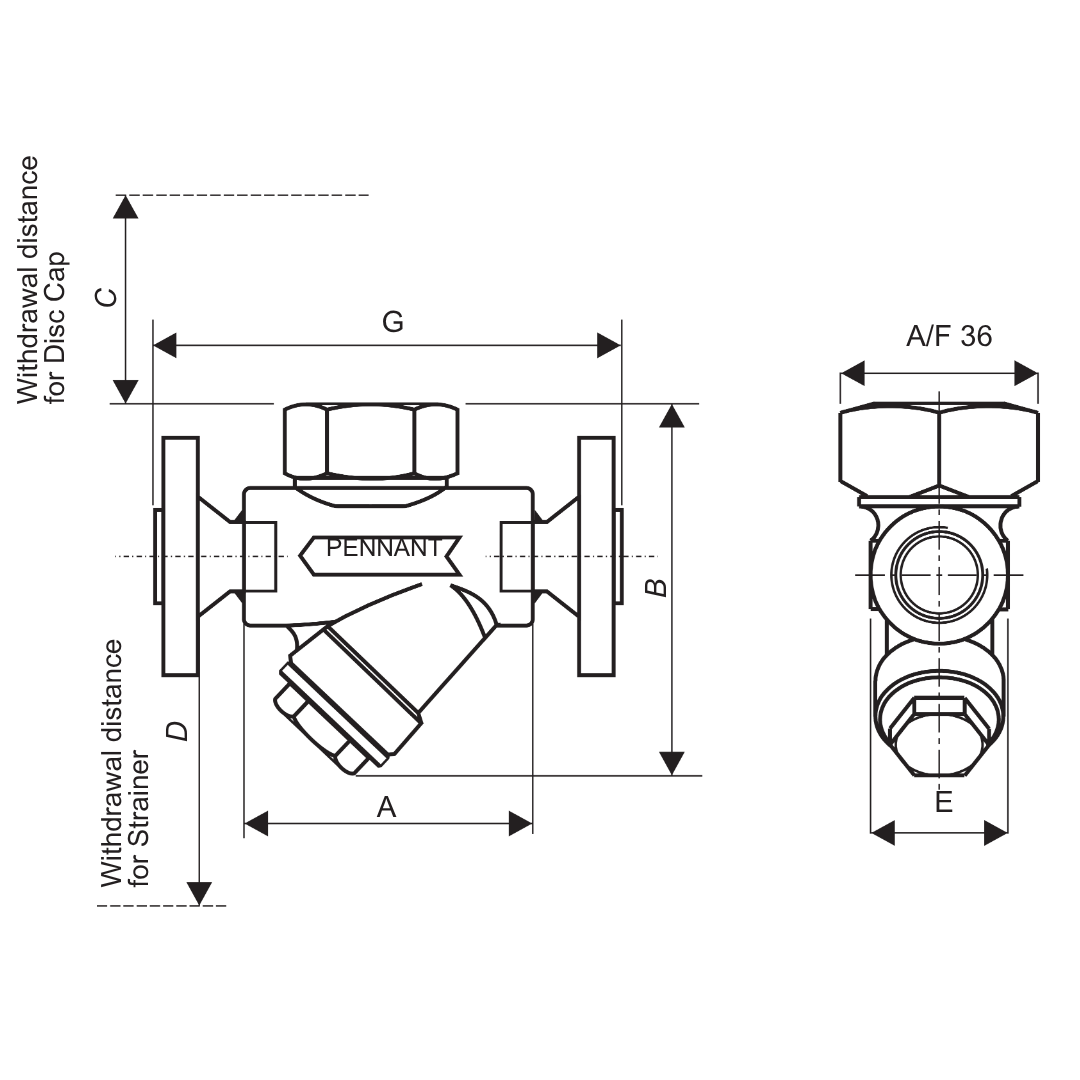

| SIZE | A | B | C | D | E | F | Wt |

|---|---|---|---|---|---|---|---|

| DN15 | 60 | 84 | 30 | 80 | 38 | 36 | 0.5 kg |

| DN20 | 68 | 84 | 30 | 80 | 38 | 36 | 0.75 kg |

| Model | Size / Rating | G | Wt |

|---|---|---|---|

| PT10 | DN15 / #150 | 138 | 1.70 kg |

| PT10 | DN20 / #150 | 152 | 2.4 kg |

1) Inlet Pressure in bar(g)

2) Back Pressure in bar(g)

3) Operating Temperature in oC

4) Condensate Load in kg/hr

5) Size & Model

6) End Connections

7) IBR/Non-lBR