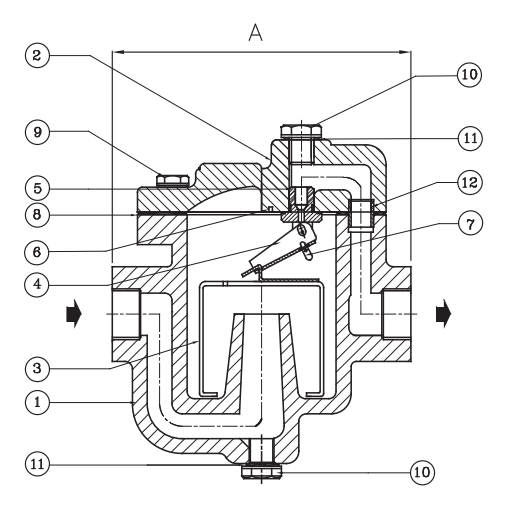

Inverted bucket steam trap with all stainless steel internals. Best suited for equipment drains with medium to heavy condensate loads. Intermittent operation.

The inverted bucket arrangement operates on the density difference between steam and water, giving a cyclic operation for discharge of the accumulated condensate. High condensate handling capacities even at low pressure, permit the use of small trap sizes to suit many applications.

220 oC

16 bar(g)

CAST IRON

End connection: Screwed NPT / BSPT / BSP

| NO. | PART | MATERIAL | QTY. |

|---|---|---|---|

| 1 | BODY | CAST IRON | 01 |

| 2 | COVER | CAST IRON | 01 |

| 3 | BUCKET ASSLY | AISI 304 | 01 |

| 4 | LEVER ASSLY. | AISI 304 | 01 |

| 5 | VALVE SEAT (HARDENED) | AISI 410/420 | 01 |

| 6 | BRACKET | AISI 304 | 01 |

| 7 | VALVE PIN (HARDENED) | AISI 410/420 | 01 |

| 8 | GASKET (COVER) | NON CAF | 01 |

| 9 | BOLT | HIGH TENSILE | 06 |

| 10 | PLUG | CARBON STEEL | 02 |

| 11 | GASKET (PLUG) | COPPER | 02 |

| 12 | LOCATING TUBE | AISI 304 | 01 |

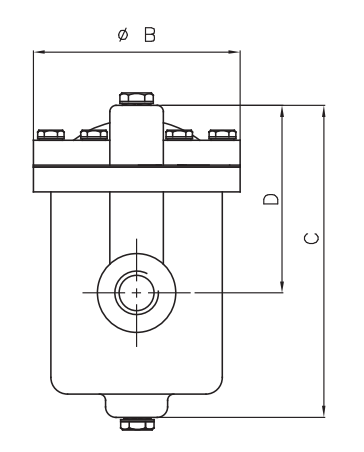

| MODEL | SIZE | A | B | C | D | Wt. |

|---|---|---|---|---|---|---|

| PT22 | DN15, 20 | 120 | 100 | 130 | 71 | 2.7 kg |

1) Inlet Pressure in bar(g)

2) Back Pressure in bar(g)

3) Operating Temperature in oC

4) Condensate Load in kg/hr

5) Size & Model

6) End Connections