PT14BM high pressure thermostatic steam trap is made of forged body with bimetallic controller assembly, inbuilt strainer and stainless-steel internals. Best suited for high pressure steam trace lines, header drip legs, heating coils and various process and heating applications.

Excellent resistance to water hammer. Tight Shut-off, No Steam Loss. Easy Maintenance – No Need of removing trap from the piping system to clean/ replace internals. Long lasting modulating discharge. Excellent air venting capacity.

565 oC @ 104 bar(g)

430.9 bar(g) @380 oC

F22 CL3

End connection: Socket Weld / Butt Weld / Flanged

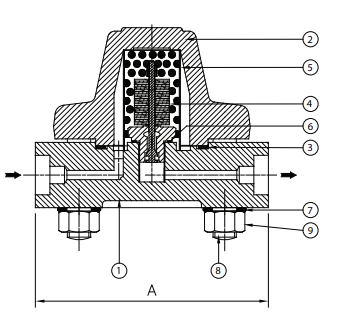

| NO | PART NAME | MATERIAL | QTY |

|---|---|---|---|

| 1 | BODY | ASTM A182 GR. F22 CL3 | 1 |

| 2 | COVER | ASTM A182 GR. F22 CL3 | 1 |

| 3 | COVER GASKET | SPIRAL WOUND GASKET WITH GRAPHITE AISI304 | 1 |

| 4 | CONTROLLER ASSLY | BIMETAL | 1 |

| 5 | STRAINER SCREEN | AISI 304 40 Mesh, ⌀6 Perforation |

1 |

| 6 | CONTROLLER ASSLY GASKET | AISI 304 | 1 |

| 7 | WASHER | 45C8 | 8 |

| 8 | STUDS | ASTM A193 GR. B16 | 8 |

| 9 | NUTS | ASTM A194 GR. B7 | 8 |

| 10 | LABEL | AISI 304 | 1 |

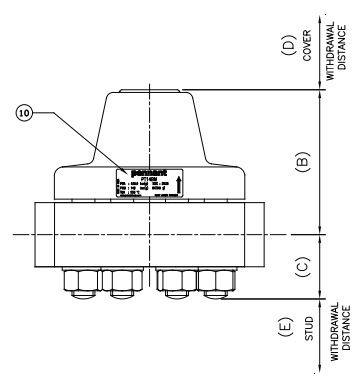

| MODEL | SIZE | A | B | C | D | E | WEIGHT |

|---|---|---|---|---|---|---|---|

| PT14BM | DN15 – 25 | 200 | 126 | 56 | 100 | 100 | 15.4 Kg |

1) Inlet Pressure in bar(g)

2) Back Pressure in bar(g)

3) Operating Temperature in oC

4) Condensate Load in kg/hr

5) Size & End Connections

6) IBR/NIBR